Deammonification = EssDe ®

S::Select ®

Sedimentation of activated sludge, i.e., settling velocity, is the central parameter for the design and operation of an entire wastewater treatment plant. S::Select® drastically accelerates sedimentation of the activated sludge in the final clarifiers. Bulking sludge no longer arises and sludge thickening is significantly improved. Further effects of the more compact sludge are a denser floc filter, which markedly reduces the solids in the plant effluent.S::Select® - significant performance increase of the biologyS::Select® generates aerobic granules and permanently maintains this optimum sludge properties. The treatment process is sustainably stabilized hereby and the nitrification performance significantly increased while maintaining a high denitrification potential. |

| Instead of expanding, biological reactor basins were decommissioned. | |

| Additional municipalities will be connected in the near future to wwt-plant Glarnerland, resulting in a significant load increase (30%). To make matters worse, the system did suffer from bulking sludge (ISV up to 800 ml/g) for decades - particularly in the winter months. After S::Select® was successfully implemented, the planned expansion from 4 to 6 streets was cancelled. In addition, 2 of the existing 4 streets were temporarily taken out of service. The effluent quality has improved significantly (suspended solids 3 - 5 mg/l, visibility >2.0 m) despite the significant increase in load (more than doubled). |

|

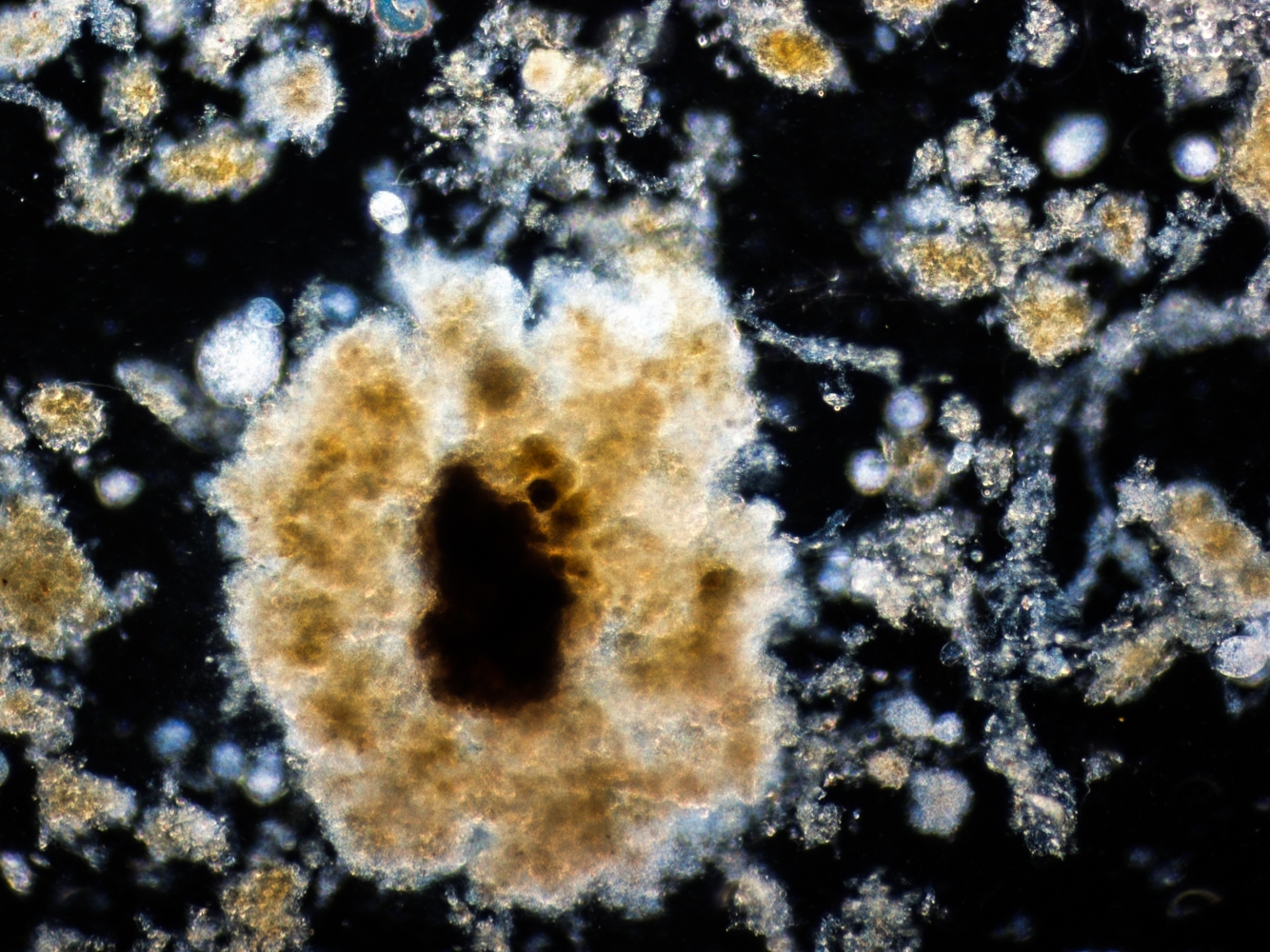

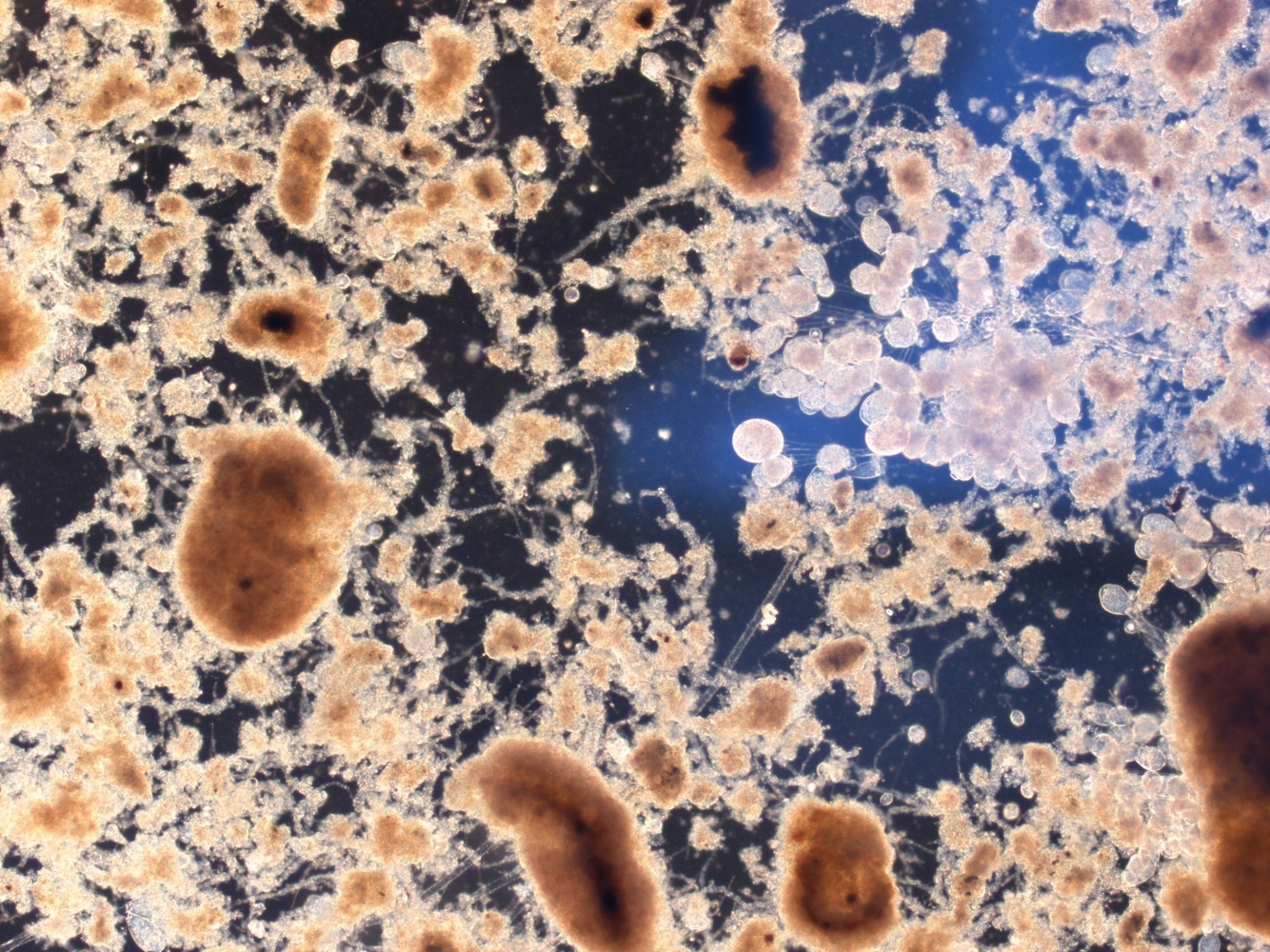

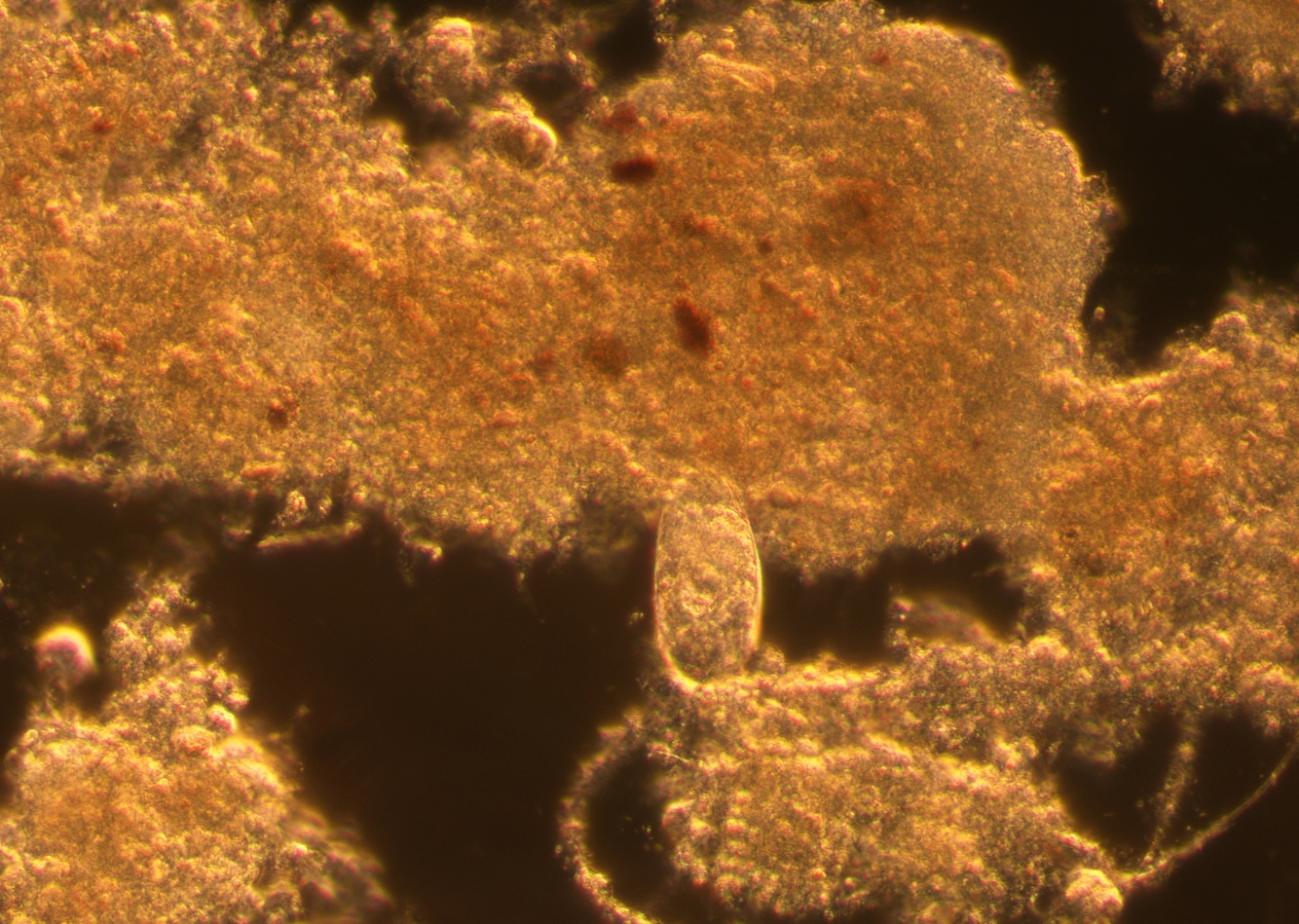

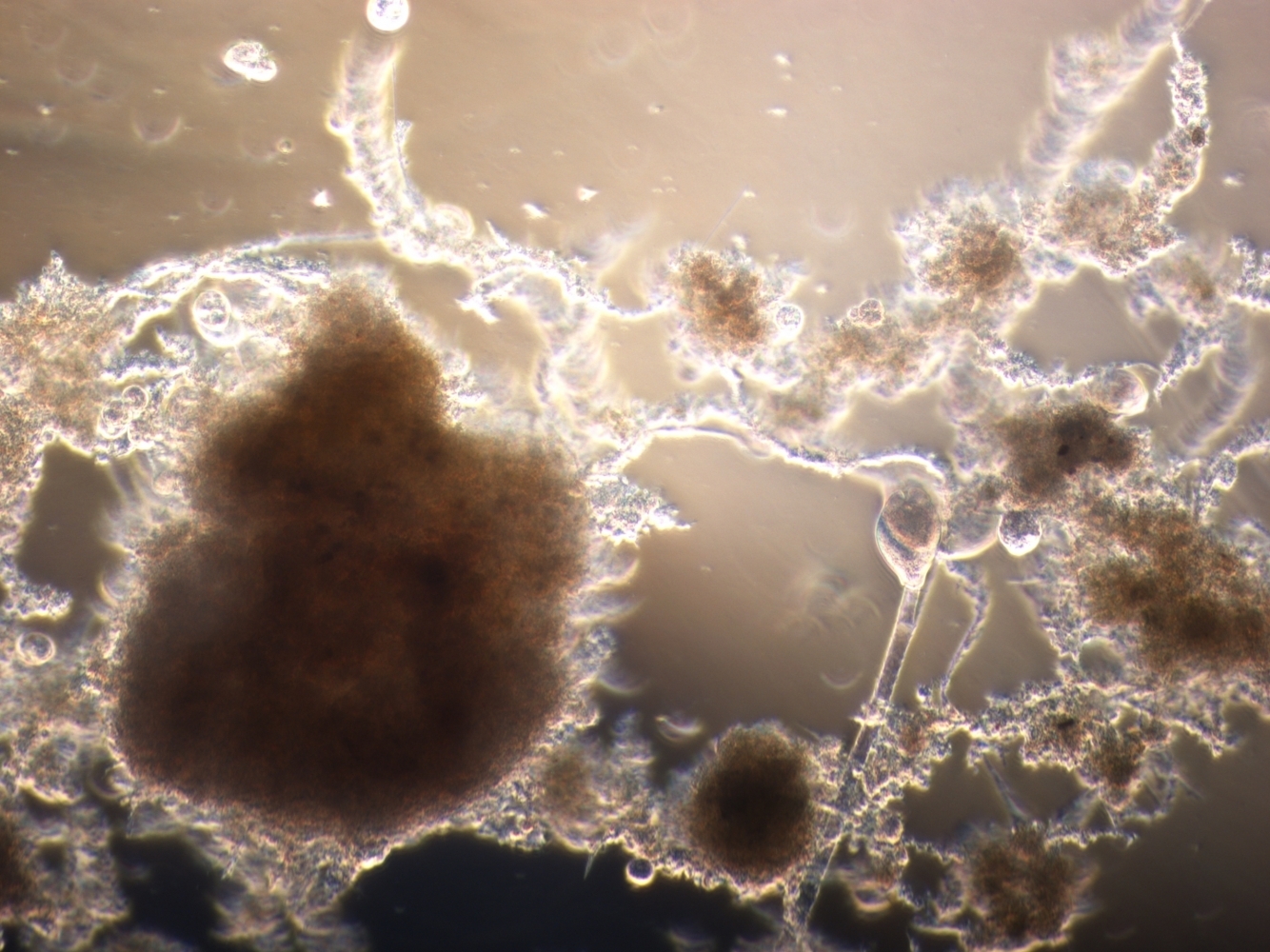

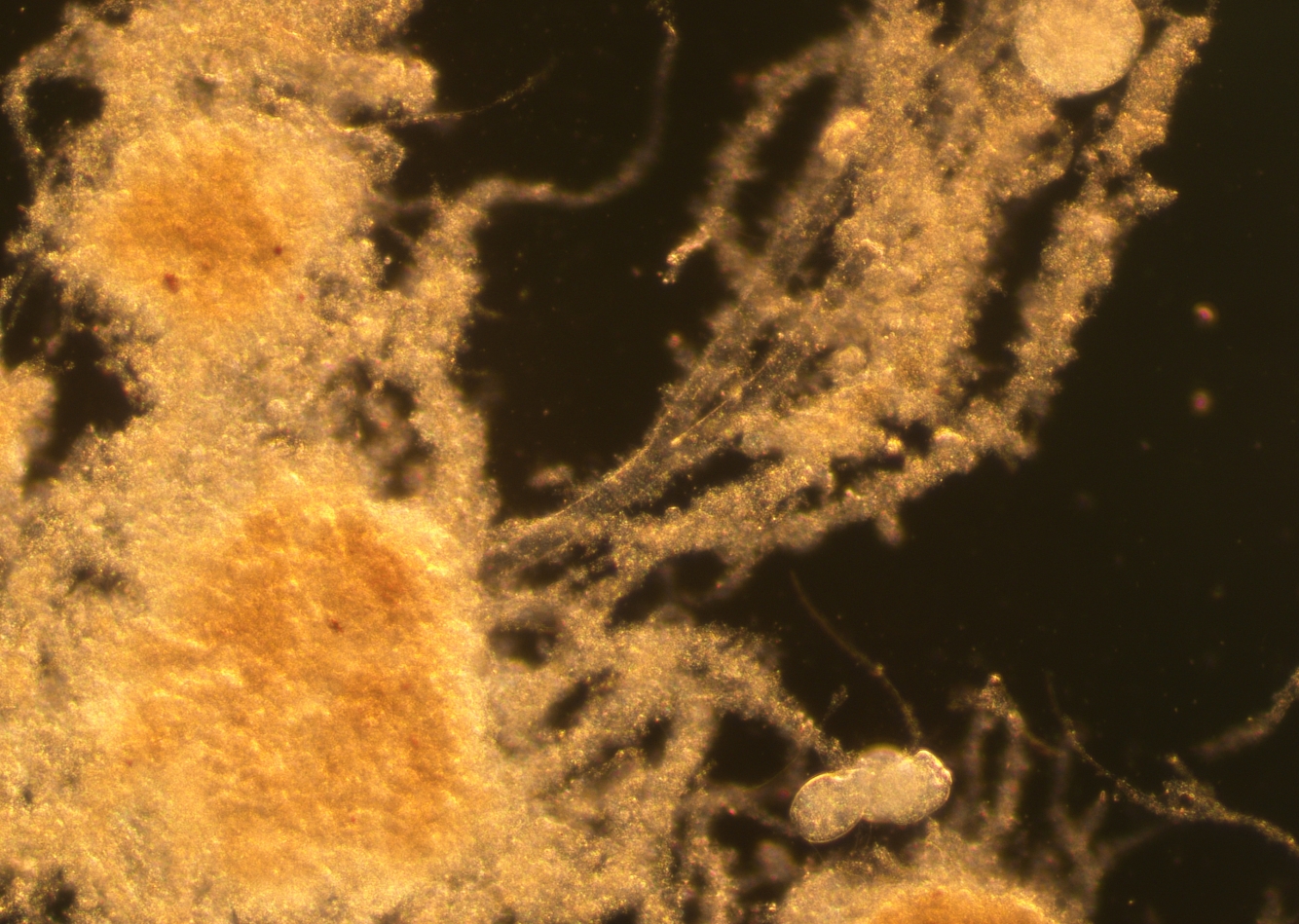

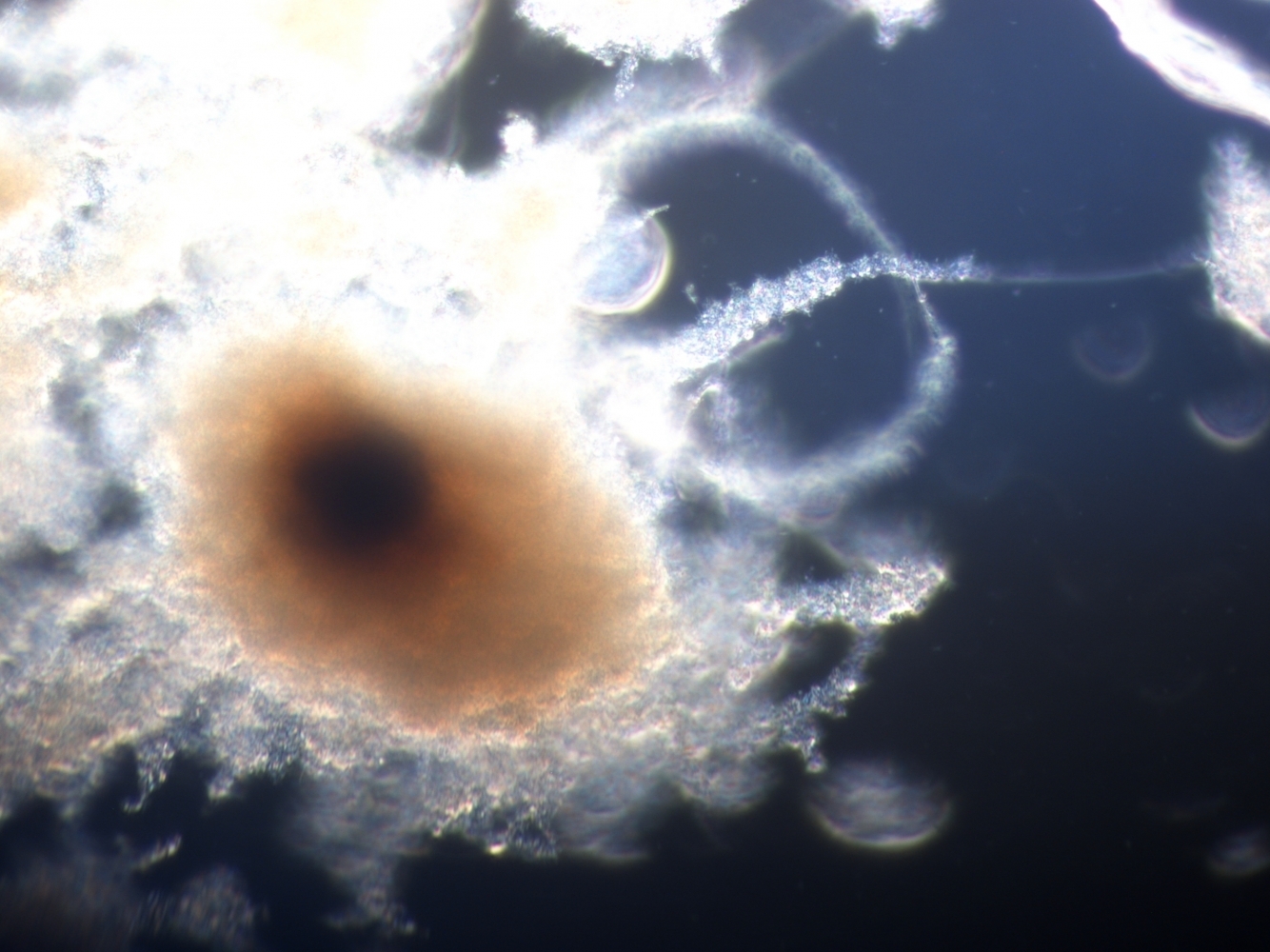

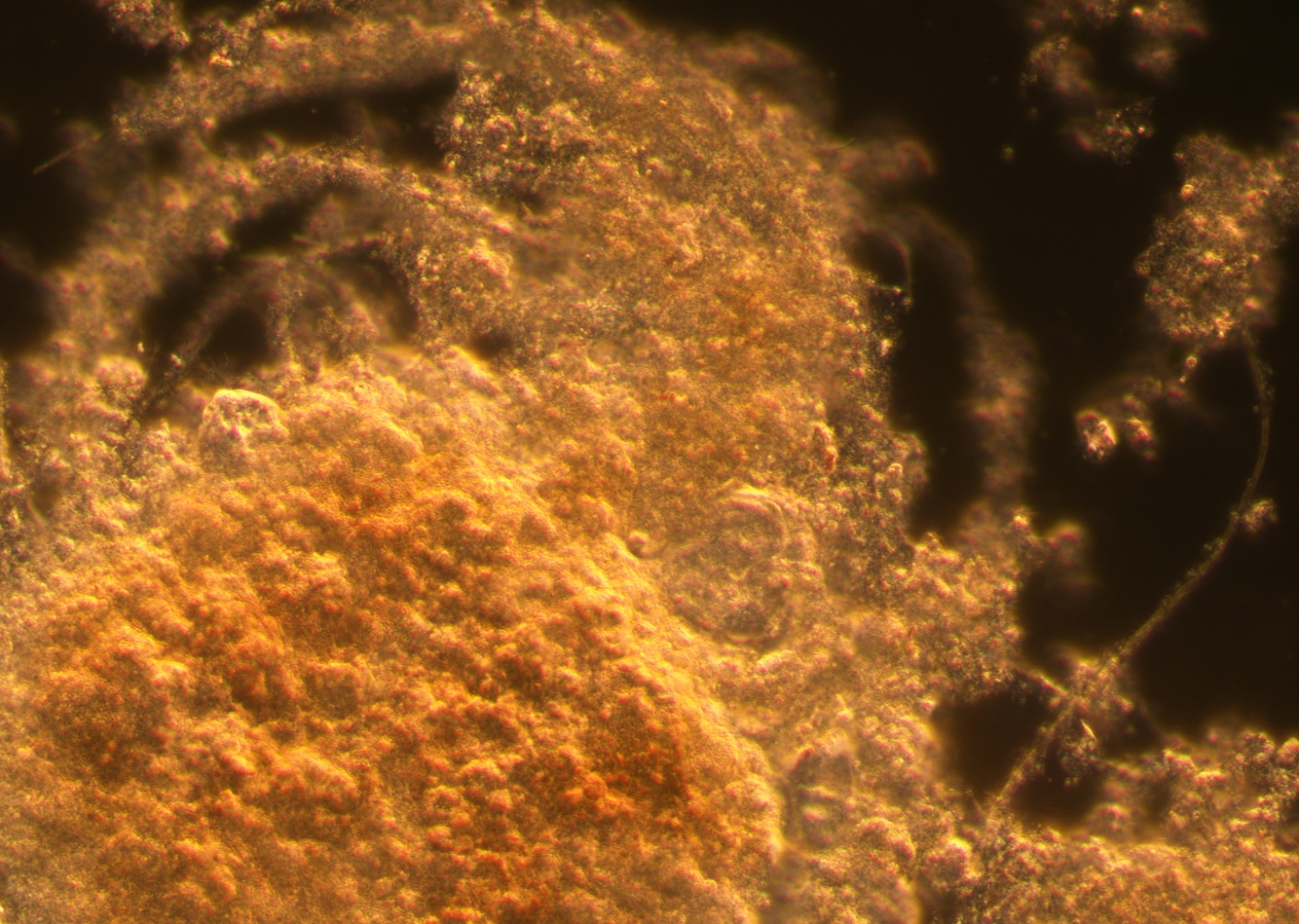

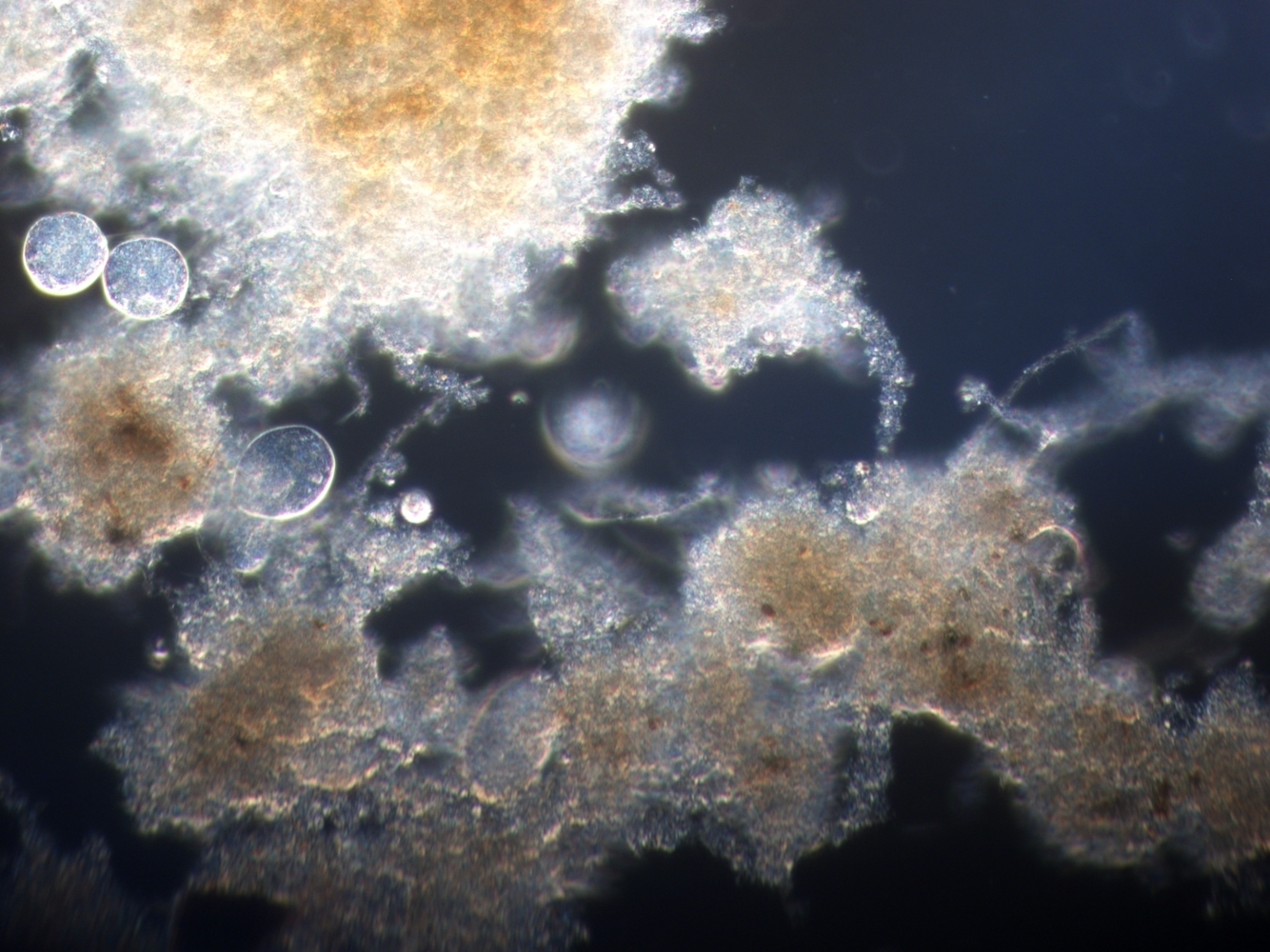

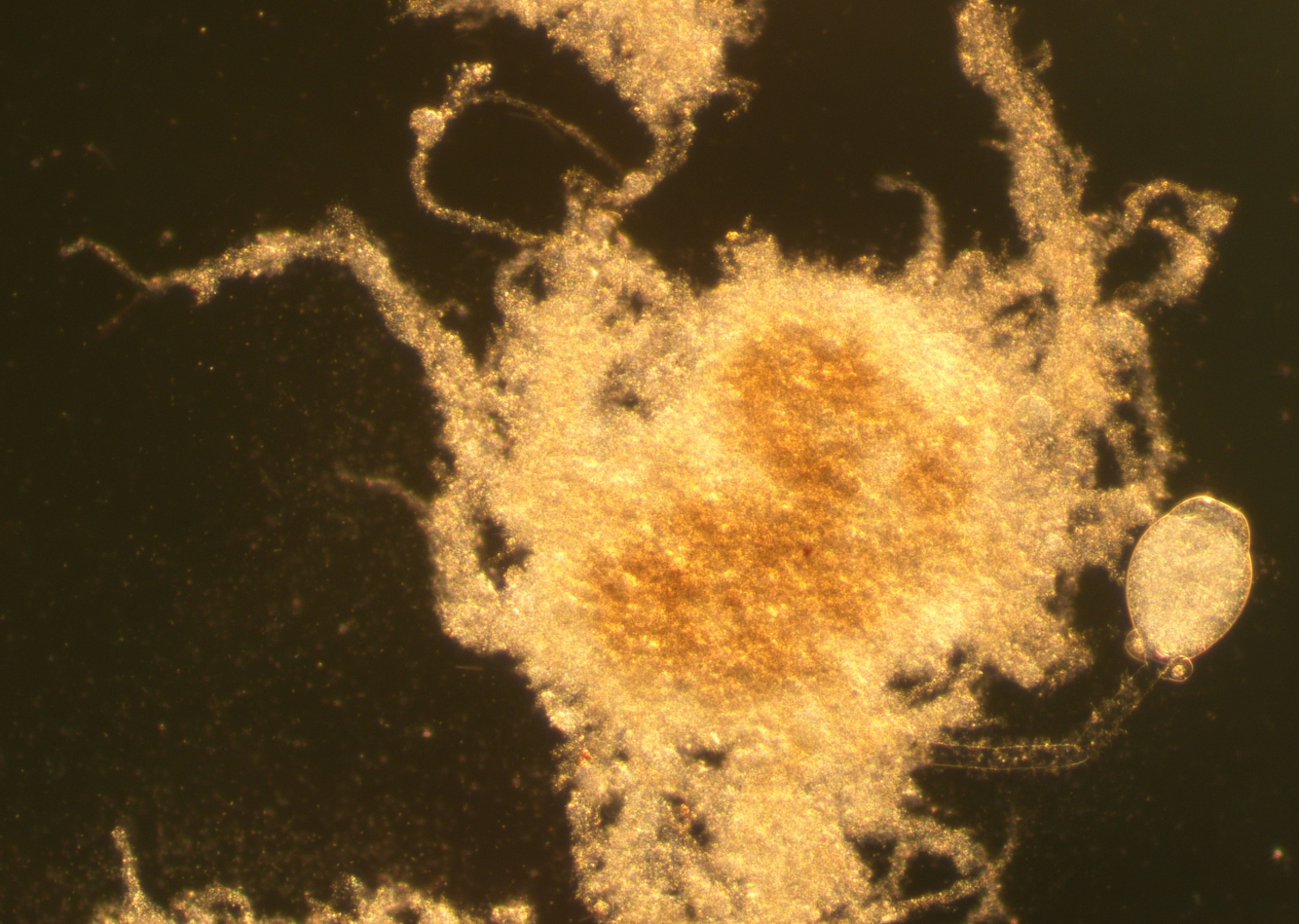

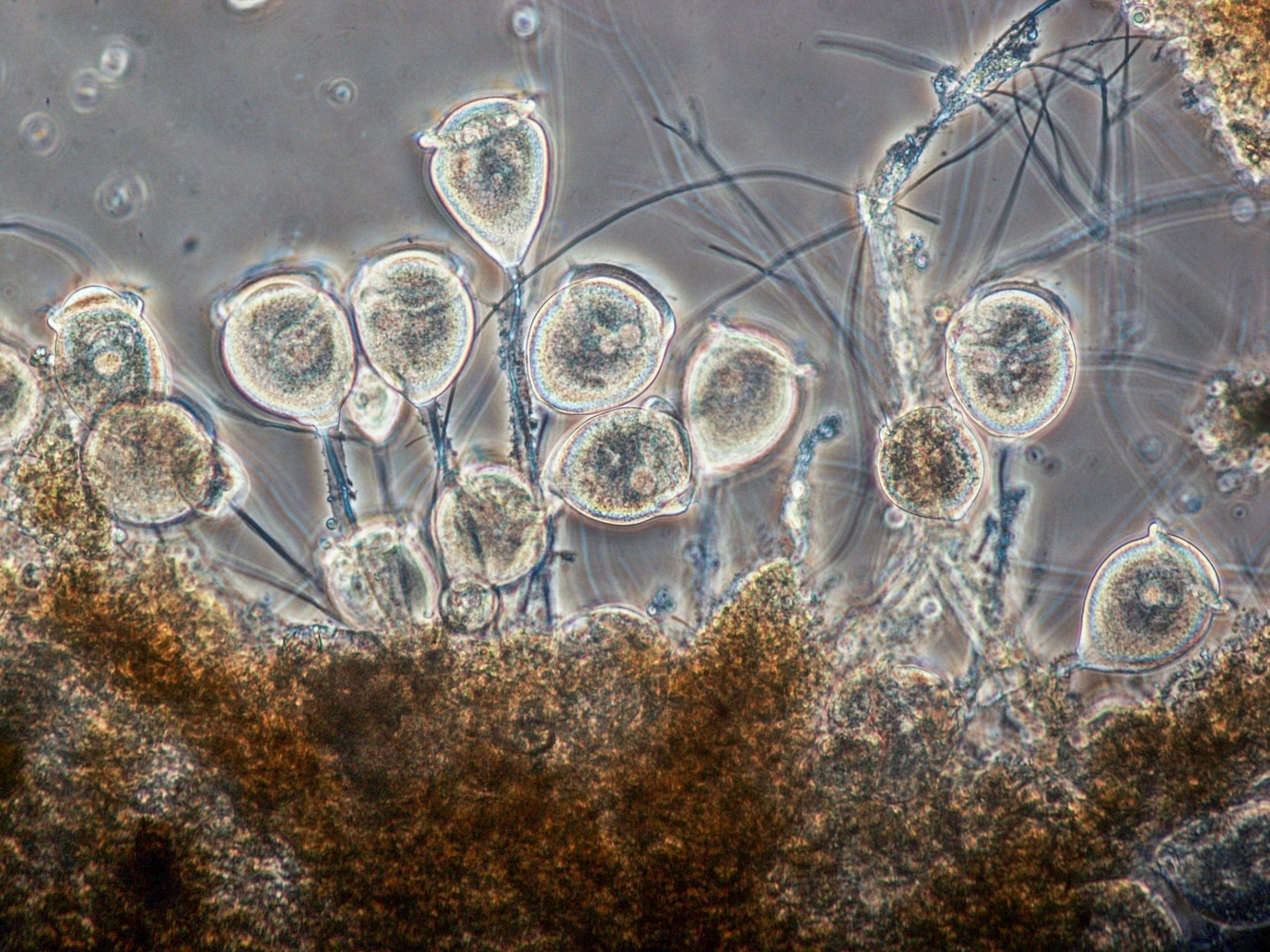

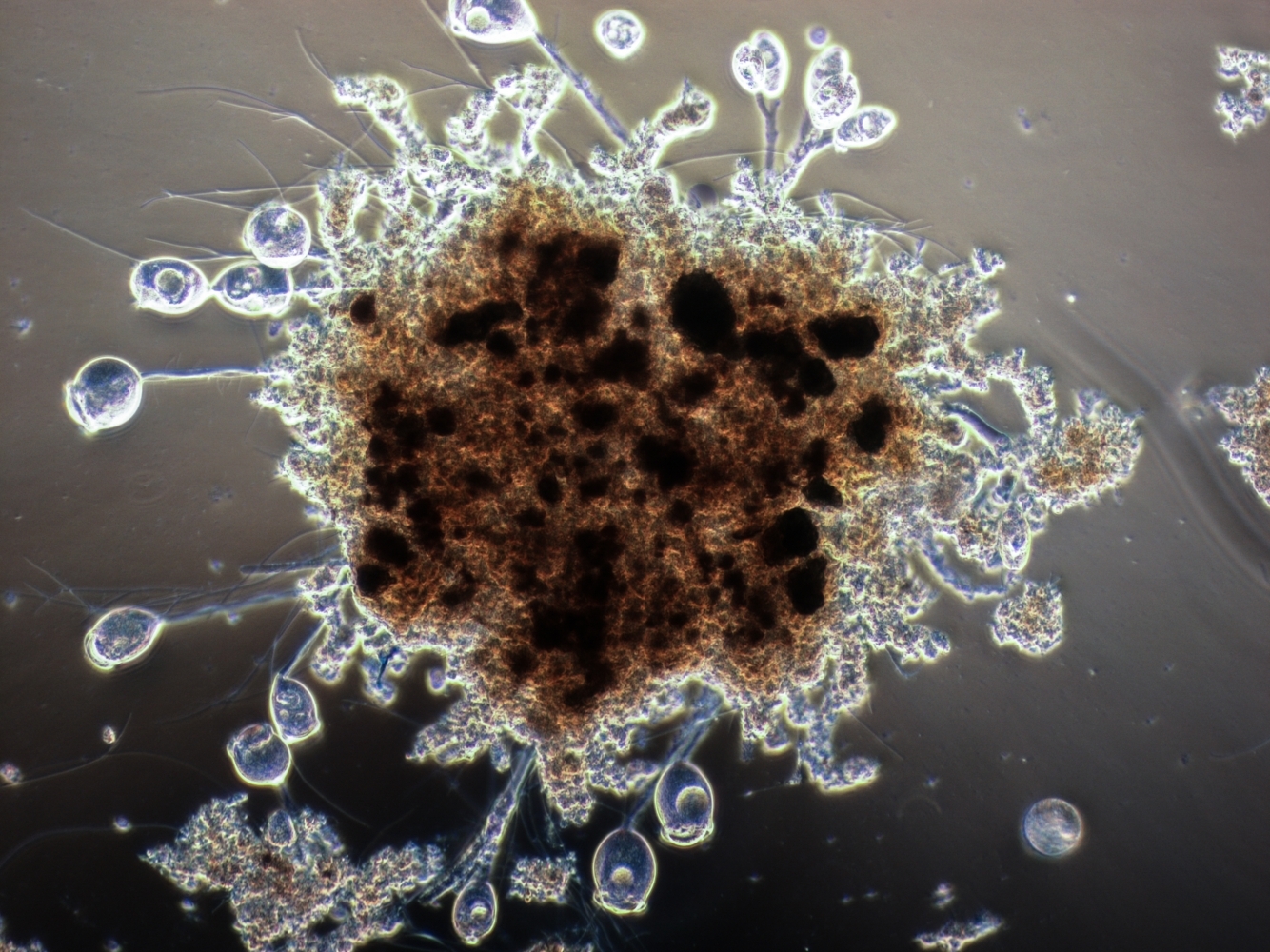

Unlike conventional activated sludge systems with suspended floc-type biomass or carrier-based systems (such as MBBR), S::Select® is an activated process using aerobic granular sludge (AGS) (Pat.):For granulation, the initially flocculent biomass is animated to form a biofilm. The common flocculent sludge structure changes into an aerobic granular sludge structure. As well as the sludge settling properties are drastically improved. The S::Select® technology also permanently maintains the aerobic granular sludge structure. The specific purification performance (kg/kg) improves significantly (nitrification). |

|

| The activated sludge settles much faster (guaranteed >3 m/h). Corresponding to this, volumes of the biological reactor basins and settling tanks can be set much smaller. At the same time, the specific sludge activity increases significantly. In addition to the nitrification capacity, the denitrification capacity also increases to a large extent. This results in a strong recovery of alkalinity, a stable flocculant structure, a low suspensa concentration and a very good visibility depth. Filamentous organisms are part of the flocs and perform well due to their large specific surface area. Together with the granules, they form a dense sludge bed in the final sedimentation tank, which provides a significant filtering effect and ensures extremely low suspensa values, while settling rapidly at a high sedimentation rate. |

High quality and competent supportThe design of the S::Select® is based on the experience of many operation years. The selectors are made of high-quality stainless steel and welded according highest standards. The solid design with quality components ensures a low-maintenance continuous operation. Together with the customer, our employees work out the optimum integration into the existing wwt process and provide intensive support during the implementation and start-up phase. In addition, our team is also available for concerns after the successful process integration. |